| |

|

| |

|

| |

|

Grand prix

(Award by Minister of Economy, Trade and Industry)

"Circle" by Moritaka Yamanishi |

Winner is "Circle" by Moritaka Yamanishi

JFW-JC Textile Contest is now established as the first-step stage for textile creators around the world, and is highly reputed. The originality, technology, and expression of competing items are sure signs of the possibilityes of Japan textile business. Among 303 competitors and 446 works, this year's grand prix, Award by Minister of Economy, Trade and Industry, went to "Circle" by Moritaka Yamanishi, after a long discussion by the jury about his unexpected circular weaving. Finally the winner was Mr. Moritaka Yamanishi. He was highly evaluated for his talent in dreaming and the possibility of textiles.

The awarding ceremony was held in the event space from 17:50 on the 15th day, and awards were donated to winners by Ms Makiko Minagawa, chief of the jury, after her overall review lecture.

Grand prix, Award by Minister of Economy, Trade and Industry, 1,000, 000 yen

"Circle" by Moritaka Yamanishi

Gold award, Award by Director of Manufacturing Industry Bureau, 300,000 yen

"Leggiero" by Takashi Watanabe

"Cotton Knit" by Chinatsu Katoh

Freshman award, 200,000 yen

"COCOON" by Megumi Aikawa

Student award, 200,000 yen

"My Border" by Shiori Akiyama

Jury's special award, 100,000 yen

"Sepia" by Akira Kanda

Technology award, 100,000 yen

"Magic Pan" by Yasumitsu Sakai

Artistic work award, 100,000 yen

"Kidoairaku" by Yasuhiro Yasuda

Trend award, 100,000 yen

Toshiyuki Kaneko

Ecology award, 100,000 yen

"Yasuragi" by Keiko Koguchi

Print award, 100,000 yen

"Yosai" by Hiromi Nakakihara |

|

|

|

|

Gold award,Award by Director of Manufacturing Industry Bureau

"Leggiero"

by Takashi Watanabe |

Gold award, Award by Director of Manufacturing Industry Bureau

"Cotton Knit"

by Chinatsu Kato |

Freshman award

"COCOON"

by Megumi Aikawa |

Student award

"My Border"

by Shiori Akiyama |

Winning words and awarded words are displayed at the textile contest corner of the promotion zone. |

| |

|

| |

|

| |

New values added to fabrics

Dyeing and processing add new values to the expression and touch of textiles. Distinguished dyeing and processing shops are exhibiting in JFW-JC.

|

| Soto Group, crease processing (Geosurf) |

Soto Group: "Denimool" or denim-touch wool

A new product of Soto Group is "Denimool Collabo." It features dyeing effects of different colors as a new version of "Denimool" noted for denim-touch wool with a sense of surface volume. Made of wool and wool-blended textile, Denimool expresses various touches when washed again and again.

"Geosurf" features creasing with geometric and solid sense, and "Biolana" is noted for its mechanical original touch and lightness. Geosurf is applied in synthetic and cellulose fibers, and has original mat and gloss varying depending on the viewing angle. Biolana is applied to mixed material of high wool content, and vintage finish is OK.

Soto Group: Booth No. F-27

|

| Komatsu Seiren Co., Ltd.: Cotton on surface side, nylon on reverse side. |

Komatsu Seiren Co., Ltd.: Specialist in raising technology

Komatsu Seiren Co., Ltd. is mainly (1) developing new scouring techniques, (2) producing light, thin, and high density fabrics using ultra-fine fibers, and (3) manufacturing synthetic fibers for outerware. Last year's topic was processing of light weight and high density, and shape retaining type. This year, fine raising technique is added to the shape retaining process, and a further advanced feel of material is noticed.

In the recent trend, natural fibers are preferred, the company uses cotton on the surface side and nylon on the reverse side, and the reverse side is manufactured by complex material by thin film processing with humidity permeating function. The reverse side is dyed in a trend color, not limited to function only.

Komatsu Seiren Co., Ltd.: Booth No. F-05

|

| Marumasu Co., Ltd. Low impact dyeing |

Marumasu Co., Ltd. Low impact dyeing

Marumasu Co., Ltd. introduces processing by low impact dyeing by suppressing environmental impact, and printing by ink jet. Low impact dyeing contributes not only to environmental protection, but also to maintenance and improvement of quality of textile by softening the touch. Thin fabric materials are likely to shrink or distort, the dyeing and processing technology of the company may be powerful and outstanding.

Exclusively for organic cotton, they develop low impact processed products conforming to the strict regulations specified by Organic Cotton Association.

Marumasu Co., Ltd.: Booth No. J-05 |

| |

|

| |

|

| |

|

Panelists discussing collaboration between different producers |

A new facet produced by collaboration of different producers

"Only by changing the producer, multiple products are created from one material." This is a new business model realized through collaboration of different industries, noticed together with production and processing beyond the boundary of origins of produce. To promote this trend, the forum of Dyeing and processing creation database (D/B) was established, and senders and receivers of the D/B were discussed. One of the interesting ideas is the comment given above, and it means that one material changes to a completely different expression when dyed or processed in a different place.

At a panel discussion joined by dyeing and processing works, weaving houses, and apparel industries, many opinions were exchanged. For example, "Japanese material are favored in Paris shops" (Matsuo International Corporation), "When white fabric from Hamamatsu was finished in dyeing works in Hokuriku, a completely new expression of fabric was created" (Fukuda Orimono,Ltd), "Originality is created from the collaboration of weaving and dyeing from yarns." Many others. Panelists emphasized that a new value is created by collaboration with new partners.

[Coordinator]

Masao Matsuda, project manager of Organization for Small & Medium Enterprises and Regional Innovation(SMRJ)

[Panel]

Hitoshi Takakura, executive officer of Matsuo International Corporation

Masatoshi Tanabe, director of Asahi Senshoku Ltd.

Masami Tatsumi, president of Tatsumi Weaving Co., Ltd.

Yasushi Fukuda, Represenrtative of Fukuda Orimono, Ltd.

Akihiro Matsukawa, president of Marumasu Co., Ltd |

| |

|

| |

|

| |

|

|

Mesh leather item manufactured like knit (aptform) |

Polarization and punching leather realizing lightness and sense of future (writtenafterwards) |

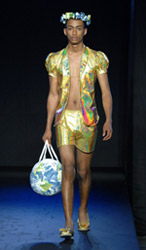

Fashion show of Tokyo-made pig skin

「aptform」×「writtenafterwards」

PIGGY'S SPECIAL sponsored by Tokyo Leather Industry Promotion Association began as the appealing point for Tokyo-made pig skin which occupies 70 percent of its nation-wide production as a fashion material. Continuing every year since 1982, this year marks the 27th anniversary, and this show has been held six times recently at the JFW-JC site. Every time young designers are invited to express new charm and possibility of pig skin. This year's designers are Michail Ginnis of aptform, and Yoshikazu Yamagata and Kentaro Tamai of writtenafterwards.

The subject of aptform is Juxtapositions, it is attempted to provide the leather with surface changes and stretchability. Cardigan-style jackets using mesh leather and other new materials like leather knit are fresh and attractive.

The subject of writtenafterwards is "Shoulder the earth," and the world of the brand associated with bags, shoes and ware is appealing. |

| |

|

| |

|

| |

PIGGY'S SPECIAL Students' collection was held twice on the 16th, at 13:30 and 15:00. A total of 54 works by students from 12 schools belonging to Metoropolitan Tokyo Professional Institution Association attracted an audience. Every year unusual designs by unexpected uses of leather are interesting. This year, the works were relatively traditional, including cut-off and patchwork items.

The models wearing colorful clothes and walking on the stage were also students.

|

|

PIGGY'S SPECIAL Students' collection was very exciting. |

|

| |

|

| |

|

| |

|

KYOKO HIGA in designer collaboration show |

Designer of KYOKO HIGA

Ms Kyoko Higa

99% made from Japanese materials

I visit JFW-JC as far as much time permits. Visitors were only a few some years ago, but are increasing recently after change of method of exhibition and improvement in sense of show. I expect more visitors will come in future.

My brand is favored by many repeaters overseas. The first reason is the material. The material is tough, not creasing easily, and not deformed in silhouette while wearing. It's a shock for overseas consumers. They understand when I explain it's the power of Japan's technology. So, my clothes are made from Japanese materials by 99 percent.

|

| |

|

| |

|

| |

K-A Trading: Booth No. A-18

Natural fibers surpassing chemical fibers

K-A trading originally developed Pidocco, 100% cotton, stretchable woven fabric. An optimum elongation rate suited to the application can be set freely in two ways. For pants and other use, if desired to stretch in lateral direction, not so much in longitudinal direction, the shrinkage rate of weft and warp can be changed. The numerical data by KES method proves that the function is on the same level as synthetic fibers.

In addition to stretchability, it features also soft touch, drape, crispness, and coolness. Not using polyurethane, the tightening force is natural, and it is fatigue-free if worn for a long time. The yarn count is from 40 count two-ply yarn to 80 count two-ply yarn. |

Left: before processing, right: completed by shrinking.

|

Liwai Japan: Booth No. C-05

Buttons of original colors and patterns

Leeway Japan is producing a wide variety of buttons and rivets. The head office is located in Hong Kong, the company has been mainly exporting to Europe and America for many years. By its original know-how, the house is offering creative and innovative colors and patterns of buttons not seen before in Japan. Popular among 109 Line and various apparel makers. Options are delivered in 3 weeks after sample presentation, and quick response is applicable. The factory is in Guangdong Province, China, and delivery to sewing factories in China is smooth and quick. Of course, you can negotiate in Japan. |

Buttons for jeans

|

Tango Textile Industrial Association

- Tango Fashion Week Committee: Booth No. E-12

Trend materials on the background of silk technology

Tango Textile Industrial Association - Tango Fashion Week Committee is a group of 16 companies consisting of 8 Japanese fashion and 8 Western fashion. In the district of Tango, the technology of silk, heavy shirting and hard twisting is traditional. Soft touch or volume feel is added according to the trend, and attractive textiles are manufactured. Blending silk with polyester or wool, or Japanese paper (washi), and cashmere touch is realized from 100% silk by beaver finish, and other versatile silk textiles are shown including the tweed and Matelasse. |

Matelasse of silk-wool blend

|

Hironen Co., Ltd.: Booth No. F-25

Crease-resistant "Mobile Luxe"

Hironen is proposing Mobile Luxe, a crease-resistant textile using PTT fiber "Solotex," and Wine Dyeing by using waste grapes after making wine. Mobile Luxe is realized by the original know-how in the preparation process. Twenty items including coats are displayed. A rare Solotex piece dyeing is a must to see. The down product using Solotex in the padding is high in restoring property, and it is easy to carry in a long travel. Colors realized by wine dyeing include violet, pink and yellow. Samples of silk and Tencel-cotton blend are on the show. |

Crease-resistant if put in pouch and packed in bag

Wine Dyeing

|

Cielo Azur Creation: Booth No. G-02

Technology is highly evaluated home and abroad

Cielo Azur Creation is a gathering of four weaving shops specialized in dobby, jacquard, weft piling (also known as corduroy), and selvage fabric, and original textiles are proposed. The technical powers are high, and the textiles of the group are employed by many European houses. A special selvage corner provided to show the popularity in Europe. |

Employed by famous houses in Europe

|

|

| |

|

|