|

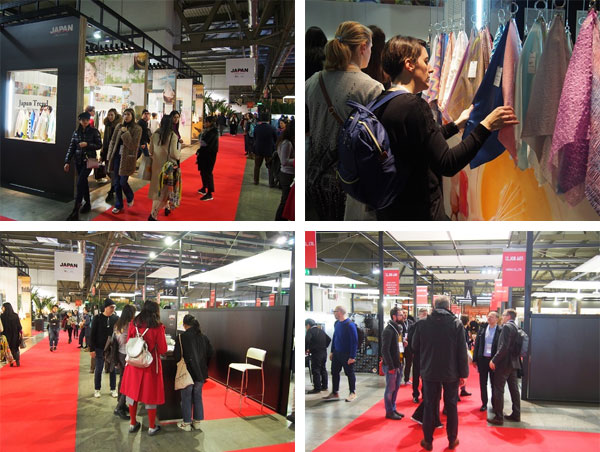

Photo:The Japan Observatory at MU2021SS |

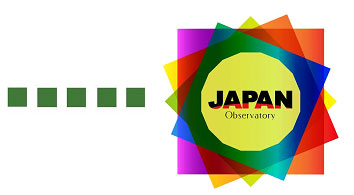

![INDEX[1] “The Japan Observatory” at Milano Unica 2023 S/S Japanese companies scheduled to participate in Milano Unica](images/title_index_01.gif) The 34th edition of Milano Unica will be held over two days, Feb. 1-2, at Rho Fieramilano in Milan, Italy and is set to feature < The Japan Observatory > (JOB), co-organised by the Japan Fashion Week Organization (JFW) and the Japan External Trade Organization (JETRO). JOB opted against physical participation for a total of three times since the Feb. edition held in 2020 due to the global COVID-19 pandemic. But despite leveraging E-Milano Unica Connect to make its presence felt via digital means, the significance of (and need for) an opportunity and platform for buyers to actually see and touch fabrics remained uppermost in mind all the while, hence this turnaround. Despite the unfavourable infection status, regular exhibitors are highly motivated to participate and we are delighted to announce the JOB scale as follows: ten companies plus one group in the physical exhibitors’ space, plus fabrics from twelve companies to be displayed in a newly installed JOB Plus booth, providing business opportunities for SMEs who are unable to send in manpower to the fair venue. Prior to the show, we are pleased to introduce the JOB physical participants at Milano Unica, where buyers from globally renowned brands converge. The 34th Edition of Milano Unica Show period: Feb. 1-2, 2022 (Tue. & Wed.) The Japan Observatory at Milano Unica 2023SS Venue: Rho Fieramilano Hall 12 (provisional) Outline >>> Exhibitors >>>  ![INDEX[2] <Introduction of exhibitors>](images/title_index_02.gif) STYLEM TAKISADA-OSAKA CO., LTD. Showcasing a wealth of sustainable fabrics STYLEM TAKISADA-OSAKA will mark their 12th participation in JOB on this occasion. Assisted by their local subsidiary in Italy and their business agency in Milan, they are capable of handling business at the fair, even in the absence of staff from Japan due to COVID-19 related travel restrictions. Their eagerness to engage in business is clear; summed up as follows: ‘Europe is a huge and important market, which is why we have our Milan and Paris bases. We even established a showroom in Milan in 2020.’ Underpinning their presence are abundant products and colour variations, plus scope to handle even small-batch orders. Highlights include 100% organic cotton amid a comprehensive line-up of other blends on show, most of which use cotton from India and Turkey. Their abundant and varied repertoire, unique and unrivalled, is what sets them apart in no uncertain terms. They have also been providing axial filaments, supplied as recycled nylon and polyester. ‘Although fabrics made with such filaments are often provided as woven taffeta, we can propose alternatives using the same filaments but different weaving methods for even greater variety.’ They even prepare compound fabrics processed by tentering. In addition to their range are diverse sustainable fabrics, including cupro and acetate, alongside textiles finished with environmentally-friendly methods. We ensure that buyers can look forward to the widest possible convergence of eco-aware fabrics at their booth. SILK TEXTILES GLOBAL PROMOTION CONSORTIUM Presenting traditional technicity originating from Kyoto The business aim of the SILK TEXTILES GLOBAL PROMOTION CONSORTIUM is to enhance alignment of the three traditional textile industry players: Nishijin, Tango and Yuzen, from each production hub in Kyoto Prefecture, with five of its companies set to make their debut in the JOB area on this occasion.MORISAN from Nishijin will present the ‘NISHIJINORI-KINRAN’ series, one highlight of which is JAPANBLUE. This textile, as the name suggests, is woven with blue slit-yarns forming three-dimensional motifs, using a technique that paves the way to accelerate the weaving of original motifs in a shorter span. MIYASHIN, meanwhile, is set to showcase outstanding textile development ability, including those with hard-twisting silk yarns that generate a three-dimensional surface effect, alongside silk-washi fabrics representing a highly focused ecological material. The Creative Workshop ITOASOBI, specialising in design yarns, sums up Europe as ‘An attractive market.’ Gracing their event line-up will be unique go-to products like woven silk-ribbon fabrics using tapes 4mm wide for warp and weft as well as woven textiles combining silk and thinned wood material (regenerated fibre). TAYUH TEXTILE INDUSTRY CORP., in contrast, develops a collection leveraging twisting and weaving techniques nurtured in Tango chirimen (silk crepe) manufacturing. The <Aya-shusu Design> for example, twill/satin with houndstooth, features 100% silk and hard-twisting weft yarn for a specific texture. <Mon Design> (Newspaper), meanwhile, is a woven jacquard fabric with a newspaper motif. TAMIYA RADEN optimise the kimono obi technique. <RADEN TEXTILE> is interwoven with yarns made of mother-of-pearl, while leather yarns comprise the <LEATHER TEXTILE>. Even yarns made from washi painted with urushi (lacquer) are available. <JFW Textile Online Salon:MIYASHIN> https://jfw-textile-online.com/textile?user=259&lang=en JAPAN DENIM Environmentally-friendly denim Three companies representing JAPAN DENIM from Hiroshima Prefecture will also join JOB. SAKAMOTO DENIM has mitigated its environmental impact with zero cleaning agents and harnessed its own original dyeing system using electrolysed and room temperature water to reduce CO2 emissions. They are pleased to showcase denim fabrics eco-dyed with this technique, alongside natural indigo-dyed denim, denim using organic cotton and other standard denim items that are affordably priced. SANYO SENKO, who strive to ‘enhance recognition of their finishing technique in the US/Europe,’ are set to introduce finishing techniques like gradational discharge and DUSTY/BIGGIE processing. These help them stand out and set them apart, dovetailing nicely with a one-stop handling approach, handling textile production to sales across the board. Top of mind during this, their third participation, is the intention to ‘boost awareness as well as acquire trends and other insights.’ SHINOHARA TEXTILE is focusing all its efforts on advancing environmental measures, which includes converting and regenerating in-house energy and repurposing it for other equipment to save power. They will be showcasing < TP9106 >; eco-dyed Tencel denim and < PE9-SOLO >; a denim-like twill made with solution-dyed recycled PET. Blending multiple colours during the spinning process elicits a mélange effect, excellent anti-pilling property and rubbing fastness. <JFW Textile Online Salon:SANYO SENKO> https://jfw-textile-online.com/textile?user=243&lang=en  Photo: Gradational discharge processing by SANYO SENO CO., LTD. KAWAGOSHIMASA CO., LTD. Outstanding planning ability together with unique creativity. KAWAGOSHIMASA, now set to debut at JOB, is cultivating the European market by setting up a representative office in London. Its verdict? ‘Many areas remain undeveloped in Europe, with significant potential for growth.’ The company constantly stocks products made in various domestic textile regions and China and sells fabrics such as synthetics, natural fibre-related knits and woven fabrics alike. With peerless planning and a range of textiles on offer, they have been ceaselessly striving to roll out new products unlike larger-scale textile traders, with a wide-ranging genre from menswear, ladieswear and hats right up to industrial materials. They also boast abundant exporting records to numerous overseas countries, reflecting the efforts of their top-ranked team operation in this area with the persons in charge. Visitors can look forward to eco-nylon fabric using regenerated yarns and a special texture, applied to accessories as well as clothes. The company has also risen to the challenge of post-processing to create product-dyed finishing with nylon: no easy task. The result sees their original grey fabric transformed with an eye-catching fade-out feel, reminiscent of degradation/discoloration. And that’s not all - the selection also includes Japan-made washable wool-linen fabric finished with an elaborate twist and with a premium feel; a top-selling staple in Japan.  Photo: Wool-linen TOYOSHIMA & CO., LTD. Appealing sustainability The top priority for this, the third participation in JOB for TOYOSHIMA & CO., LTD, is on their textile exports for Europe, their key market. Toyoshima has scope to transform its range across the board, from raw cotton to textiles. It is also a textile manufacturer that excels in developing original products and trading in locally made products to existing overseas customers in the US and Europe. Their focus this time will be on its knit jacquard using <REFIBRA>, upcycling waste textiles and products with the circular economy in mind. Complementing it will be woven fabric using cotton/linen for warp and Tencel A100 for weft for a casually mixed end texture featuring charm a-plenty. The crimping for the weft Tencel uses zero polyurethane; emphasizing lightweight and semi-permanent stretchability. Sun-drying - a process ideally suited to the balmy and windy surrounds of the Enshu Region - rounds off the process. Eliciting a dry-touch alongside the creasing that natural drying promotes, it comes courtesy of a sustainable dyeing processing method which cuts water consumption by up to 25-50%. Finally come Karl Mayer items using a Tencel luxury line, < TENCEL LUXE >. This is an eco-sustainable fabric which remains lightweight, while retaining a premium and luxury feel and texture. <JFW Textile Online Salon:TOYOSHIMA & CO., LTD.> https://jfw-textile-online.com/textile?user=246&lang=en  TAKISADA-NAGOYA CO., LTD. Ability of proposals tailored to the market TAKISADA-NAGOYA marks their 12th participation in the JOB with the following outlook: ‘Despite the fact Europe and the US are different markets, they have one thing in common - they both require environmentally aware fabrics, regardless of the company scale.’ They aim to ‘listen to local buyers and update local information so that feedback can be reflected in their further product development.’ Unmissable exhibits include <1060140>, a fabric with ultra-fine air vents forming ripstop woven patterns and with functionality, water-repellence and stretchability as well as anti-crease qualities. <14-5336>, meanwhile, is a cardboard material using hard-twisting triacetate compound yarns that retains a dry and refreshing skin touch. And the secret to its stand-out silhouette is a fluffy and spongy texture combined with a supple yet tense feel. <81-41069> is a post-processed fabric using recycled polyester but with an overwhelmingly natural feel. It is sustainable, lightweight and well-tailored to the eye, with unrivalled comfort, stretchability and quick-drying qualities. The company is rolling out a complete range of original fabrics made for the market, which even include hybrid fabrics for the domestic market that have been adjusted and customized for those in Europe. An operational function leveraging an abundance of stock compounds its advantage. <JFW Textile Online Salon:TAKISADA-NAGOYA CO., LTD.>

|

This e-mail magazine is sent to all individuals having visited our show, JFW-Japan Creation in the past and/or who have registered for an e-mail magazine subscription on the website as well as to all members concerned. |

Published by : The JFW Japan Fashion Week Organization Textile Div. |