![INDEX[0] JFW Textile Fair 2021A/W](https://www.japancreation.com/english/mailmag_jfw_textile_news/201225_0118_JFW_Textile_Fair_2021aw/images/jfw_textile_fair_2021aw.jpg)

|

![INDEX[0] JFW Textile Fair 2021A/W](https://www.japancreation.com/english/mailmag_jfw_textile_news/201225_0118_JFW_Textile_Fair_2021aw/images/jfw_textile_fair_2021aw.jpg) |

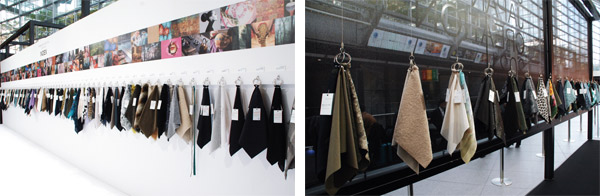

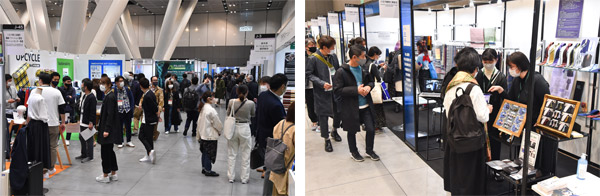

![INDEX[1] Visitor numbers exceed expectations](https://www.japancreation.com/english/mailmag_jfw_textile_news/201225_0118_JFW_Textile_Fair_2021aw/images/title_index_01.gif) Post-Show Report - Part 1 The <JFW JAPAN CREATION 2021 (JFW-JC2021)> and <Premium Textile Japan 2021 Autumn/Winter (PTJ2021AW)> shows organised by the Japan Fashion Week Organization (JFW)) were held on November 18 and 19 at the Tokyo International Forum venue, located in the Yurakucho district of Tokyo. Both ended safety and attracted a higher number of visitors than expected, despite the ongoing COVID-19 pandemic. On this occasion, both shows were held in full compliance with preventive measures, by reducing the number of exhibitors and booths by around 20%, to widen thoroughfares and avoid crowded conditions. The scales of the shows were as follows: <JFW-JC> 47 entries, 242 companies/168.9 booths (*Previous yr.: 84 entries, 294 companies/210.3 booths) <PTJ> 66 entries/92.75 booths (*Previous yr.: 85 entries/116.5 booths) The total number of visitors recorded was 12,626 (previous yr.: 16,811), which exceeded our expectation, despite the circumstances. The apparel industry has been struggling, significantly affected by the ongoing impact of COVID-19 throughout this year and textile manufacturers had virtually no platforms via which to showcase their fabrics for the following season, due to cancelled textile shows. Accordingly, the shows held were awash with enthusiastic negotiations throughout as well as a wealth of buyer feedback: ‘We want to see new materials.’  [Show period] Nov. 18-19, 2020 (Wed. & Thu.) [Venue] Tokyo International Forum / Exhibition hall [Organiser] Japan Fashion Week Organization [No. of exhibitors] JFW-JC2021: 47 entries, 242 companies/168.9 booth nos. PTJ2021AW: 66 entries, 92.75 booths [No. of visitors] 12,626 (*Previous year: 16,811) Our post-show report of the JFW-JC2021, PTJ2021AW fairs will be distributed in two editions, Parts 1 and 2. Part.1 • Visitors’ feedback • Exhibitors’ feedback Part.2 • Textile Workshop - Let’s learn Japan fabrics! - • Pigskin Fashion Show - < PIGGY’S SPECIAL > • The JFW Sustainability Project  ![INDEX[2] ‘I have long wanted to touch and feel fabrics!’](https://www.japancreation.com/english/mailmag_jfw_textile_news/201225_0118_JFW_Textile_Fair_2021aw/images/title_index_02.gif) Visitors’ feedback Much of the visitors’ feedback included comments like; ‘Several textile fairs were cancelled due to COVID-19 this year and we cannot even visit the textile regions. Although we can see fabrics online, I have long wanted to touch fabrics directly to examine them.’ (Apparel company), which proved the importance of having real (physical) shows as far as textiles are concerned given their nature. Other comments include: ‘I found the fabric I was looking for.’ (Apparel company), alongside ‘There were many diversified fabrics that cannot be found in school.’ (Student), as is often heard at every show. In terms of new exhibitors, JFW-JC received three entries and seven booths, including two entries and four booths from returning exhibitors, while PTJ hosted 14 new companies on this occasion and seven companies applied to use the newly installed small-sized booths. New exhibitors play key roles in generating momentum and opening up new opportunities to seek new fabrics. Conversely, there were also comments expressing disappointment such as ‘This time, the company we wanted to visit unfortunately did not join the show’ (Apparel company), showing how the COVID-19 calamity has affected business.  Many visitors also acclaimed the preventive measures taken by the organiser: ‘Preventive measures cannot be more or less.’, ‘There was no alternative under such circumstances’, ‘I came to the show full of determination and resolve.’ (Trading firm), ‘It was the first physical show after a long while and I felt the preventive measures were sufficient.’, ‘Preventive measures and restrictions did not disturb me so much.’ (Apparel company). Another comment reflected the importance of business: ‘I do not care about COVID-19 so much. If we do, we can never continue business.’ It is a constant question to support economic activities and preventive measures at the same time. The < JFW Sustainability Project >, which was launched from this edition onward, aims to promote the realization of a sustainable society and global environment protection. Among numerous comments heard: ‘I came to source sustainable textiles’ (Trading firm), ‘I heard that there are wide-ranging sustainable fabrics all at once.’ (Apparel company) and ‘I wanted to learn about sustainability.’ (Student). Conversely, the overall impression shows sustainability has yet to establish a strong presence among many visitors; ‘I am not so aware of sustainability.’, ‘My purpose for visiting the fair was not seeking sustainable fabrics.’, ‘Sustainability is a must-have when exporting fabrics to Europe/USA.’ (Trading company), although awareness for sustainability has not reached the Europe/USA benchmark when it comes to negotiations targeting domestic markets. Since it will certainly underpin business going forward, there will be a need to continue proposing sustainability, including activities for enlightenment till then.  ![INDEX[3] Japanese exhibitors](https://www.japancreation.com/english/mailmag_jfw_textile_news/201225_0118_JFW_Textile_Fair_2021aw/images/title_index_03.gif) Exhibitors’ feedback On this occasion, the no. of companies having indicated the newly set sustainability icon within the booths was nine (JFW-JC) and 31 (PTJ) respectively. NITTOBO INTERLINING CO., LTD. (who exhibited in JFW-JC) attracted numerous visitors as they showcased ‘interlining made by recycling and upcycling’. ‘With increasing offers of sustainable fabrics, we sense a shift in buyers’ interest towards supporting materials such as interlining, despite their cost-consciousness,’ they pointed out. OE CO., LTD./TANGO TEXTILE INDUSTRIAL ASSOCIATION is another company who showcased a sustainability-related product in GENBOKU-ZOME (raw-timber dye), which leveraged thinned wood. ‘Although our work is acclaimed overseas, cost remains a factor in Japan,’ said the company, concerning the impact of the current business stagnation. The KE’KEN Textile Testing & Certification Center participated as part of the Bishu Style initiative and took the chance to explain that they would be commencing certification work in line with the standards of the environmentally friendly organisation known as Textile Exchange (TE). The company is continuing work in readiness to acquire the international standard ISO17065, which is the benchmark to implement the new service. MIYUKI KEORI CO., LTD. promoted a ‘production system dealing till finished products’ by showcasing more fabrics alongside garments. The KITA-IWATE APPAREL INDUSTRY PROMOTION ASSOCIATION, comprising apparel manufacturers, is a returning exhibitor that showcased unrivalled techniques from each manufacturer. Despite their wide-ranging product line-up, the ‘domestic business environment for men’s and women’s apparel remains severe’, due to the ongoing COVID-19 pandemic. Underwear and training wear items remained relatively firm among other categories, according to the association.  The HAMACHIRIMEN INDUSTRIAL ASSOCIATION promoted their NAGAHAMA eco-friendly silk, ‘NecoS’, refined with materials derived from nature rather than chemical substances. To date, it was already applied for traditional crafts, but not mass production, but a patent is pending for a technique adapted for mass production. The slightly yellowish fabric is made without using any bleaching agent. The KAWADA KNITTING GROUP belonging to the TOYAMA TEXTILE & FASHION ASSOCIATION, introduced ‘tococie for SDGs›, as their second offshoot from its ‘tococie’ factory brand. This specific fabric, exclusively made for the SDGs (Sustainable Development Goals), attracted significant visitor attention and interest. FUKUI INNOVATORY TEXTILE displayed ten garment works, which were created in collaboration with BUNKA FASHION GRADUATE UNIVERSITY. The BANSHUORI KITAHARIMA INDUSTRIAL DEVELOPMENT ORGANIZATION hosted 16 companies and one association within its scope. On this occasion, as a first, they decided to participate collectively as a group instead of individually as usual, as part of efforts to acquire new customers and offset the downturn in orders due to the COVID-19 pandemic. In their local region, they have started actively producing garments and appealing directly to consumers. Consequently, their serious efforts to tackle these issues seem to have attracted numerous visitors.  At the PTJ fair, MATSUBARA CO., LTD. promoted their high-tension knit using ‘CLENSE’ as an antibacterial and antiviral finish. Although this is a product ‘basically applied to bottoms/jackets, it can also be adapted to T-shirts and masks’, which seems to have captured the interest of many visitors due to the ongoing pandemic. CRESCEND YONEZAWA showcased stoles as their mainstay alongside YONEZAWA-ORI, DANTSU (a thick handwoven carpet), woven to order in a local atelier in Yonezawa City for the company. They analysed their results as ‘so-so in terms of visitor numbers,’ and explained their wish to promote the ongoing availability of woven carpeting/matting products in their Yonezawa region, proposing applications for living/interior items. SAIEI ORIMONO CO., LTD. showcased sustainable fabrics blending silk and acetate. They also continue to pursue sustainable development as they consider: ‘Awareness of sustainability may vary between a designer and an MD, but it remains undeniably a sweeping trend.’ MARUI ORIMONO CO., LTD. presented fabrics including cotton-like polyester for shirts alongside stretch materials, reflecting an increasing shift towards telecommuting due to COVID-19. SUNCORONA ODA CO., LTD. showcased mainly organza fabrics in recycled polyester, thinly made with a fine-count yarn as well as affordable. This fabric was intended to underpin the range of sustainability-oriented items, given that many buyers remain cost-conscious about sustainable fabrics.  DAIICHI ORIMONO CO., LTD. deals with recycled polyester and as well as exporting to Europe and the USA, it has also striven to boost sales of such products within the domestic market. Their business achievement seemed favourable, given that the first-day sample selection by buyers was 1.5 times the total of the previous year. They have successfully consolidated ties with apparel companies who have strong interests in their fabrics, not only through fabric sales but also by providing sustainability-related information alongside sales records with acclaimed maisons. TORAY INDUSTRIES, INC. promoted ‘green innovation’. According to their analysis, there are buyers who source fabrics from an eco-oriented perspective and occasionally witness changes in their interest from recycled materials to those derived from plants. KANEMASA KNITTING CO., LTD. stockpiles their original ‘SUVIN recycled organic’ yarns, which blend extra-long staple Indian organic cotton and Suven cotton waste. They presented this product in diversified knitting structures. A new exhibitor; NAGOYA SPINNING CO., LTD., strove to boost prominence of its original textile brand; ‘YA/E’, which comprises four categories, including environmentally friendly materials like organic cotton and plant dyeing.  SUZUKI BLEACH & DYEING CO., LTD. focused on promoting their antibacterial products by showcasing antiviral sprays using silver-ion, which can be sprayed onto clothes and/or interior-related products and is considered equally effective for pollen and house dust alike. They have newly developed ‘BOTANIVIR’, using a nature-derived functional component for finishing. This is an antiviral finishing technique using grapefruit seeds. YOSHIDA SENKO CO., LTD. showcased products under a trio of themes, namely: SUSTAINABLE, EXTRAORDINARY and NEW BASIC. The SUSTAINABLE collection included wool, cotton, cupro and undyed raw material. KURASHIKIZOME comprised six companies belonging to the Okayama Prefectural Textile Dyeing Industries Association. The association has implemented original finishing standards in compliance with the hazardous chemical list indicated by ZDHC and certifies textile products which do not retain or emit toxic substances at each stage of the process at finishing factories as <KURASHIIZOME>. They commented that they intended to secure safety and security by improving the system required by manufacturers. The trading company TOYOSHIMA & CO., LTD. focused on ‘food textile’, using dye from food to be discarded, such as vegetables/ingredients, while MARUSA CO., LTD. showcased line-ups according to four keywords: working from home, home-staying time, outdoor and MINO-WASHI, centring on the new lifestyle having emerged since COVID-19.  ![INDEX[4] Overseas exhibitors:](https://www.japancreation.com/english/mailmag_jfw_textile_news/201225_0118_JFW_Textile_Fair_2021aw/images/title_index_04.gif) Exhibitors’ feedback Participation by overseas exhibitors was limited due to COVID-19 travel restrictions, although some businesses still managed to participate thanks to the support of local staff in Japan. Fabrics representing eight Taiwanese companies went on display in the booth of the Taiwan Textile Federation (Taiwan). They included participants like EVERET TEXTILE, who deal with European/American outdoor makers as well as being a Bluesign-certified company. When asked about sustainability, one of the participants commented; ‘Awareness of Japanese companies remains low compared with that of Europe/USA in general. We hope that consumers will lead the way for apparel.’ POLARTEC (USA) showcased their highlighted product; < Power Air >, as part of a solution to tackle the marine plastic pollution issue. The material has a specific double layered structure that excels in heat retention. CALIK DENIM (Turkey) presented their development of E-Denim using recycled yarn, which constitutes covered yarn using recycled yarn as a core. ZHANGJIAGANG AOYANG WOOL FABRIC (China), is a fabric producer using recycled wool spun from used clothes. They have acquired global certificates including GRS (Global Recycle Standard) and Ecotex. Thermore Japan pronounced themselves satisfied and commented; ‘Our existing customers came all the way from Osaka/Nagoya to visit us. The Yurakucho venue is easily accessible, even amid such a period, in our opinion.’ They showcased products including insulation of 50% recycled polyester/50% virgin polyester and insulation made from 100% recycled polyester alongside their newly launched ‘Ecodown fiber 2.0’ product.  ![INDEX[5] JFW Textile Shows in 2021](https://www.japancreation.com/english/mailmag_jfw_textile_news/201225_0118_JFW_Textile_Fair_2021aw/images/title_index_05.gif) Premium Textile Japan 2022 Spring/Summer

JFW JAPAN CREATION 2022 Premium Textile Japan 2022 Autumn/Winter

|

||||||||||||||||||||